| Search results - "spring" |

51 viewsD44 front winch bumper. Ali washer bottle. D44 rear h/d bumper. centre diff lock. 235x85x16 pirelli muds. OME +2" springs & shocks. front diff guard. side tree bars. wired for roof CB. Aux fuse block. safari snorkel. extended wading tubes. the list goes on...

|

|

With lava and hot spring at Rekjanes117 views

|

|

10 Cracked smoking parking brake drum338 viewsNote the crack in the face of the brake. This showed mangled parking brake springs and other bits. Also a bit of melted rubber was drooling out of the crack. Started to remove the brake caliper and enjoying the flies in 45 deg C heat. Ah, the wonderful Aussie climate in January.

|

|

Windich Springs, People not in our group221 views

|

|

Cooking Roast at Pierre Springs225 views

|

|

The roast is ging well, Pierre Springs206 views

|

|

Durba Springs206 views

|

|

Durba Springs202 views

|

|

Durba Springs198 views

|

|

Durba Springs192 views

|

|

Campsite, Durba Springs222 views

|

|

Sunrise Durba Springs185 views

|

|

Llamsrecovery mode installation53 viewsSpring lock inconspicuous

|

|

Owen Springs - Towards the West MacDonnell Ranges162 views

|

|

Cruising North of Alice Springs236 views

|

|

Brake shoe arm 20 viewsCable retaining spring location

|

|

Brake shoe arm23 viewsCable retaining spring location 2

|

|

D4MY2012 Clock Spring119 viewsD4MY2012 Clock Spring

|

|

Thread upload21 viewsImage uploaded in thread 142296

|

|

new spring24 views

|

|

old spring21 views

|

|

Corrugations on the Owen Springs track219 views

|

|

6mm Heat Shrink colours 362 viewsI decided to colour code the tubing so I used 6mm electrical heat shrink.

As there is no apparent colour coding re the 3, I tried to emulate the P38 coding; #1 LR red, #2 RR blue, #3 LF yellow, and #4 RF green. This was not doable as both left side air springs have green coloured tubing coming off the top of the front and rear air springs. I therefore arbitrarily chose the Left Rear to be red; Left Front green; Right Front yellow; Right Rear blue; and for the air compressor supply line, White coloured heat shrink. Since two new lines tie into each air spring line, I made the line between the air spring and the FASKIT, a single solid colour, and the line from the FASKIT to the valve block, White, plus the related appropriate solid colour.

|

|

airbag latch hooks342 viewsAirbag retained to steering wheel by 2 latch springs located onto latch hooks of steering wheel

|

|

airbag latch springs326 viewsAirbag retained to steering wheel by 2 latch springs located onto latch hooks of steering wheel

|

|

Air parts64 viewsSubstitute airs spring parts - reuseable

|

|

Air Parts57 viewsSubstitue push fit air spring terminators for Disco 3

|

|

Thread upload4 viewsImage uploaded in thread 178588

|

|

Our Trip Apr-Aug 2008135 viewsGosford to: Broken Hill, Innamincka, Birdsville, Alice Springs, Bungle Bungle NP, Broome, Gibb River Rd to Mitchell Falls and then Kunnunurra, Darwin (for tail gate Repair), Normanton (via Roper Bar, Borroloola, Lawn Hill, Burketown), Townsville, down coast to Noosa then inland to home. TRACK TRACE BY TRACKRANGER SOFTWARE ON ASUS UMPC.

|

|

214 views

|

|

201 views

|

|

199 views

|

|

197 views

|

|

185 views

|

|

Bin Cover removed showing forward release clips that clip into the two rectangular slots.10 viewsOne has to pull up on the Bin Cover to unlatch the two metal clips, hence why release of the C pillar cover makes the bin cover removal and reinstall easier.

|

|

141 views

|

|

Thread upload8 viewsImage uploaded in thread 147264

|

|

BROKEN DETENT11 views

|

|

Mvubu in Botswana 2014119 viewsMvubu 2014 Discovery 4 TDV6 XS, Corris Grey.Snorkel, OL Bull Bar, Winch,OME Heavy Duty Coil Springs,Light Guards,17" Black Wheels,Cooper ST max,Dual Battery+Inverter,Drawer Storage,FR Rear Ladder,Hannibal Roof Rack,80L Excel Long Range Fuel Tank,HiLift Jack Points,75L Water Tank.

|

|

nice quiet spot to sleep204 views3 week spring road trip from NC to Colorado.

|

|

Clip Spring Metal FYC 500040 that holds LR together1747 viewsThe jpg is of the spring metal clip, Land Rover part number FYC 500040 that holds most of our 3 together - well at least most the interior trim parts.

If you are going to remove interior panels, you may as well stock up on a few for replacement as upon panel removal, the clips tend to spring away into deep never to be found voids within your 3.

|

|

334 views

|

|

Clock Spring / Rotary Coupler Connector from horn controls209 views

|

|

385 views

|

|

Thread upload2 viewsImage uploaded in thread 179494

|

|

Thread upload1 viewsImage uploaded in thread 209420

|

|

313 views

|

|

64 views

|

|

31 views

|

|

3D Printed Clock Spring27 views

|

|

7 views

|

|

34 views

|

|

32 views

|

|

30 views

|

|

42 views

|

|

Thread upload2 viewsImage uploaded in new thread

|

|

King Spring Lifted D3 Coiler397 views

|

|

D4_clockspring_1.png23 views

|

|

D4_clockspring_2.png23 views

|

|

DETENT SPRING AND HOUSING12 views

|

|

Dimensions - Coil spring suspension vehicles64 views

|

|

46 views

|

|

old springs 21 views

|

|

Thread upload17 viewsImage uploaded in thread 151102

|

|

King Springs Lift331 viewsSpring Lift and Safari snorkel fitted

|

|

King Springs Lift240 viewsFront Spring

|

|

King Springs Lift217 viewsRear underbody Clearance

|

|

King Springs Lift205 viewsFront underbody clearance

|

|

215 views

|

|

Bush camp 70km South of Alice Springs114 views

|

|

D3 Clockspring Unheated42 views

|

|

Springtime with the D4!178 views

|

|

EPB kit spare springs37 views

|

|

Widow maker - Alice Springs116 viewsHyper extended - Climbed the widow maker and the suspension found its way to this position by the top without any intervention.

|

|

Thread upload0 viewsImage uploaded in thread 147264

|

|

FASKIT on end view 864 viewsEnd and rear view of the FASKIT. Yellow lines are as shipped for hooking to the air supply; one line to valve/filler and other is to gauge. I will modify the arrangement to delete one of the yellow lines such that gauge line plugs into where the second yellow line is right now,(will be only one yellow tube), and then the air source line will plug into the port controlled by the valve, (hidden in this view but visible in other view). When white valve is in the ON position, gauge will read air source pressure, and be available to supply air to any of the selected four air springs. When valve is closed, the gauge will show individual air pressure in each of the air springs when a jumper is run between the gauge Schrader valve and the appropriate air spring Schrader valve.

|

|

FASKIT air panel unmounted843 viewsThis is the manual air valve panel that is mounted in the "empty" space where the FBH normally resides. The gauge reads to a maximum of 25 Bar. The air tank relief valve is set just over 16.5 Bar (240 psig); the front air springs run maybe 9 Bar, (130 psig) and the rear, somewhat less, perhaps between 5 and 8 Bar. (70 to 115 psig). Max theoretical air spring pressure at full compression due to a big bump and full gross is approximately 27 Bar (390 psig).

|

|

Front King Spring Coil 248 views

|

|

Thread upload15 viewsImage uploaded in thread 171455

|

|

Thread upload3 viewsImage uploaded in new thread

|

|

Thread upload21 viewsImage uploaded in new thread

|

|

Clock Spring12 viewsImage uploaded in thread 100073

|

|

Spring in place18 views

|

|

Spring3 views

|

|

Spring14 views

|

|

Spring25 views

|

|

Picture of the engine compartment fuse panel5780 viewsEngine compartment fuse panel located near the battery. This is where F3E, (5 amp), F26E, (20 amp), Fuseable link 10E, (60 amp) and Relay 7E, the now upgraded 70 amp air compressor motor relay, part number YWB500220, (E is for Engine compartment fuse box), are all located. Fuse F35P, (5 amp), is inside the Passenger compartment behind the lower glove box door.

To keep the suspension from going down to the stops when driving, (or parked), it appears that it is only really necessary to remove F26E to depower the exhaust valve and generally keep all the valve block solenoid valves in a closed position trapping whatever air is within the air springs. F3E gets its power thru F26E, so when F26E is removed, the F3E circuit is automatically de-powered. F35P is more interesting in that battery power goes thru the ignition switch and F35P and then into the air suspension control unit. Apparently however, if F26E is removed, removing the F35P is not needed even when the engine is running.

With all fuses still in, if you have a problem, in practice, ideally, the compressor still works and will raise the 3 to an appropriate height. If so, one can then shut the engine off and allow the computers to go to sleep and then you remove the fuse(s). In actual practice, it seems that one need only pull the F26E fuse and can do so with the engine running. All the same, one might consider that the 3 is first a mobile computer, and secondly a 4x4. Computers prefer to go to sleep before the plug is pulled on them, however given that F26E circuit is always alive, then the computer never sleeps. With the fuse(s) pulled, and if you are still up, you can now be a 4x4 instead of a low rider. The whole purpose of the fuse pulling exercise is to depower the one and only system exhaust valve that is physically located within the compressor unit, (to keep it from opening), and secondarily to keep closed the four air spring solenoids within the block valves. This also shuts the air compressor down and stops the air compressor from making air even if the compressor is still good. That is why you initially need the fuse(s) in to allow the compressor to make air if it can.

|

|

Towing my 56 Chevy264 viewsI towed my Classic Chevy about 650 miles from Palm Springs to Reno, including over the Sierra Nevada mountain pass (7,085 feet (2160 meters)) and the LR3 pulled very well.

|

|

Clock spring39 views

|

|

New toys - 2" lift Lovells Gas Legend - (+100kg springs)51 views

|

|

Redg plate mounting127 viewsThe original redg plate mounting was modified. An L-shaped piece of plastic now sticks out rearward from the top of the mounting and this hooks over the back of the top edge of the bumper cover. Then 2 spring clips hold the bottom edge of the mounting in place. Proximity sensor and surround camera seen unaffected.

|

|

How to remove spring stuck behind ashtray12 views

|

|

Dogs14 viewsspringer

|

|

LRO18556 Clock spring and indicator/wiper stalk31 views

|

|

Boot lighting, looking to rear - hatch closed 543 viewsView shows the lights mounted in the rear on an early spring day.

In operation, the lights are tilted so that they shine downwards. The lights are mounted high enough up that one cannot see the LEDs from the front thru the rear view mirror; also the LEDs are so directional, that no light is thrown on the side glass.

Each assembly contains 15 LEDs, however the reflector is such that the LEDs appear to double.

|

|

Compressor Con Rod Broken 1753 viewsThe model number of this compressor is RQG500060; the model number of my replacement compressor was LR015303, the unit that was apparently being installed on the D4 vehicles as of Spring 2010. As of Fall 2011, the new replacement part number is LR023964, the same as in the 4's.

Note the number hand written on the black plate. All the compressors seem to have some number hand written on them - hand built I presume, and every unit perhaps evolving a bit differently as LR struggles to build a compressor that will last. I guess Hitachi, (the manufacturer), should be given credit for that.

|

|

Compressor Electrical Plugs 1406 viewsThis shows the two electrical connectors; the two pronger is the power to the compressor, and the multi-pin connector carries control signals. Also the temporary red plug is where the 6 mm tubing from the centre valve block connects. This line carries both the compressor and exhaust air to and from the springs.

|

|

View of mounted panel from front left side878 viewsNote that all valve handles are shown in the OFF position, (the trouble position). In this case, the air that is in the air springs, (if any), is trapped in there - that is the valve blocks cannot vent whatever air is already in the air springs as the air lines between the springs and respective valve blocks are closed off by the FASKIT valves. In operation, there may be only trouble with one air spring, (perhaps a wheel height sensor), and as such, only one valve would need to be closed. If there was complete air compressor failure, then all valves would be closed and then as required, each spring could be manually filled from an outside clean dry oil free air source.

|

|

View from front left side looking towards rear aux battery compartment under cover 647 viewsAs there is no Fuel Burning Heater in the NAS V8 petrol vehicles, there is space available to install the FASKIT panel here. The piping is such that each air spring can be isolated from the air system and then filled one at a time manually via the Schrader valve. There are five Schrader valves and five shutoff valves. The fifth valve nearest the gauge controls air from the compressor, and can provide fill up air via a jumper fill line assuming the compressor is still operational.

|

|

Empty space in NAS LR3 for location of FASKIT panel599 viewsThe empty space is available as the North America Spec gasoline engine LR3's do not have the Fuel Burning Heater installed. The air lines from the four air springs and the air tank will appear to rise up from under the headlight assembly. The lines to the front block valve assembly located behind the front right fog light will sort of run within the bumper across the front of the radiator down into behind the righthand fog light. The rear lines somewhat follow the path of the existing air feed line from the front valve assembly to compressor. Rather than be located between the left front fender liner and left metal wing however, the four lines will feed thru the empty wing space inside and above the wheel well arch and exit down by the left front mud flap. From there, the lines run along the left frame member above the air tank and then parallel the frame over top the compressor to the top of the rear left air spring where the rear air block valve assembly is located.

|

|

Wiring, (tubing), loom exiting temporarily from the front right fog light.569 viewsThe front axle air valve block is located just behind and below the fog light. Access to the valve block is by removing the right front fender liner, (or the bumper). The FASKIT lines are attached to the left and right front air spring lines at this location; also compressor air is taken from this location as well. Cutting the lines at as few different locations makes it easier to find leaks at a later date. As above, five 6mm air lines run from the FASKIT panel to the front axle air valve assembly and run within the loom. Two pair of the lines are for control of the air springs, and the fifth line taps the air supply at the valve block assembly off the compressor. This will be the air source line rather than tapping in directly to the high pressure air tank.

|

|

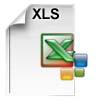

Excel file for Rotors and Brake Pads part numbers for 4.4L V8 petrol LR3769 viewsComparing the cost of the various brands of brake parts is time consuming. Once you have your parts costs, this little spreadsheet will make collating the info easier.

I did not make any provision for labour costs, but the file can be downloaded and then modified. You can change Dollars to Euros or Pounds or whatever and insert lines for labour costs as desired.

Do not pay too much attention to the $ numbers as they are a mix of US and CDN, and from differing time frames, (prior to Spring 2011) . Also the brake part numbers are for my 2005 North America spec LR3 with the petrol 4.4L V8; diesel powered and supercharged 3's may have different part numbers

|

|

Eleanor - my 2007 LR3 HSE2 viewsThis was taken in the Spring of 2014, after a good hard detail job!

|

|

Front replacement coil spring - King Springs127 views

|

|

Rear replacement coil spring - King Springs116 views

|

|

After replacement heavy duty coil springs fitted129 viewsReplacement King Spring coils fitted 22 February 2008. Oem shocks retained.

Wheel arch measurements (note that the old springs - weighing perhaps 30kg - were sitting in the boot when the "after" measurements were taken):-

FRONT

Before - 33" (84cm)

After - 35¼" (89.5cm)

REAR

Before - 33" (84cm)

After - 34¼" (86.7cm)

|

|

After replacement heavy duty coil springs fitted129 viewsReplacement King Spring coils fitted 22 February 2008. Oem shocks retained.

Wheel arch measurements (note that the old springs - weighing perhaps 30kg - were sitting in the boot when the "after" measurements were taken):-

FRONT

Before - 33" (84cm)

After - 35¼" (89.5cm)

REAR

Before - 33" (84cm)

After - 34¼" (86.7cm)

|

|

After replacement heavy duty coil springs fitted188 viewsReplacement King Spring coils fitted 22 February 2008. Oem shocks retained.

Wheel arch measurements (note that the old springs - weighing perhaps 30kg - were sitting in the boot when the "after" measurements were taken):-

FRONT

Before - 33" (84cm)

After - 35¼" (89.5cm)

REAR

Before - 33" (84cm)

After - 34¼" (86.7cm)

|

|

From wheel arch after replacement heavy duty coil springs fitted135 viewsAfter replacement heavy duty coil King Spring coils fitted 22 February 2008. Oem shocks retained.

Wheel arch measurements

FRONT

Before - 33" (84cm)

After - 35¼" (89.5cm)

|

|

Rear wheel arch measurement after replacement heavy duty coil springs fitted146 viewsAfter replacement heavy duty King Spring coils fitted 22 February 2008. Oem shocks retained.

Wheel arch measurements (note that the old springs - weighing perhaps 30kg - were sitting in the boot when the "after" measurements were taken):-

REAR

Before - 33" (84cm)

After - 34¼" (86.7cm)

|

|

Some of the dozens of Disc 2s here at work - They have been well used and have taken a real hammering by the guys - Megga sub zero temps and tortuous terrain - One even spent several months buried in snow prior to recover in the spring.148 views

|

|

LR020590 KIT - COMPRESSOR 1481 viewsThere are 4 main parts you can get besides a whole compressor. This is the one with only a spring, o-ring and rubber valve.

YWB500220 electrical, fuse & relay, relay ENGINE COMPARTMENT, 70 amp 1

LR020590 KIT - COMPRESSOR 1

JPO500010 KIT - COMPRESSOR 1

VUB504700 - Dehydrator PARTS

|

|

65 views

|

|

83 views

|

|

Thread upload2 viewsImage uploaded in thread 179258

|

|

Rear King Spring Coil 265 views

|

|

Stanley Chasm - Alice Springs244 views

|

|

Early morning dip in hot springs83 views

|

|

A dip in the thermal spring at Mataranka139 views

|

|

Clock spring wiring pinout ish70 views

|

|

The faulty unit (secondary gear / torque clutch)376 viewsShowing the inadequate circlip retaining land, ripped iopen by the normal spring tension. Should never have been made of plastic...

|

|

Gear box casing showing wear from screaming friction...409 views...once the circlip has bust through the inadequate retaining land, the spring presses on the (other) gearbox casing, forcing the secondary gear to wear on the gear box casing where shown, there being no adequate provision for end-thrust (even though helical gearing would mandate that, to cope with the NORMAL axial vector forces produced) resulting from spring pressure on the other gearbox casing face pushing the gear into this face.

|

|

Wrangler HP and russian spring holds the wheel136 views

|

|

"Spring" series 2008 in the Solent90 views

|

|

101 viewsDown in the river bottom there were a bunch of temporary run-off springs. These will be gone in a day or two.

|

|

Thread upload12 viewsImage uploaded in new thread

|

|

Thread upload6 viewsImage uploaded in thread 147264

|

|

Thread upload12 viewsImage uploaded in thread 147264

|

|

100 viewsGood view of the run-off swollen river and another spring.

|

|

Thread upload8 viewsImage uploaded in thread 163608

|

|

100 viewsAnother temporary run-off spring.

|

|

345 views

|

|

Thread upload12 viewsImage uploaded in thread 18882

|

|

Thread upload10 viewsImage uploaded in thread 18882

|

|

Thread upload12 viewsImage uploaded in thread 18882

|

|

Towing outfit201 viewsTowing our Trailcraft 5.4m "Panorama Dirt Road" caravan (March 2008).

Heavy duty springs and 150mm hitch riser on LR "plough" has made the outfit level. There's a slight nose-up attitude and some pitching front and back whilst under-way. We're looking forward to taking delivery of a Mitchell Bros towbar so that we can use our Hayman Reece weight distribution hitch (which will correct the nose-up and reduce the front-back pitch).

|

|

Car and Horsebox235 viewsLoading at Spring Farm

|

|

111 views

|

|

Taking a dip949 viewsCALENDAR ENTRY 2009. First off-road trip with new King Spring lift fitted to the coiler. Taken 12t Jan 08 in Whitecliff Quarry, near Coleford in the Forest of Dean.

|

|

|

|

|